- Home

- How to

- How to

- Services

- Services

- Maintenance Plan

- Location

- Guides

- Guides

- No Hot Water – Self help

- Unvented Water Heater

- Unvented Water Heater Faults

- G3 Building Regulations

- Thermal Store Water Heaters

- Thermal Store Faults

- Gledhill ElectraMate

- Gledhill PulsaCoil

- Gledhill Torrent

- Gledhill Stainless Lite

- OSO Unvented Heater

- MegaFlo – Heatrae Sadia

- Santon Premier Plus

- Albion

- Manco Riverstream and Powerstream

- Manco Gladiator & Stirling

- Telford Tempest

- Safety Considerations Unvented Cylinders

- Reduce Your Water Heating Bill

- Range Tribune

- About Us

- About us

- Contact

Unvented Water Cylinder Engineers

G3 Qualified

-

Call Now

0161 941 5571

How Does Unvented Cylinder Maintenance Save You Money? 2 Apr 2024 Heating water for use in your home isn’t optional. Your family needs to bathe, you have dishes that must be washed, and you likely use hot water for other things around the house. Of course, all that heated water requires fuel, either gas or electric, and you’ll pay for each unit you use. The good news is that there are many ways to make your water heater more efficient to reduce the amount of energy it uses. One of the best options is a Maintenance Plan. How does maintenance save you money? Improved Heating One of the most important ways… Read more

How Does Unvented Cylinder Maintenance Save You Money? 2 Apr 2024 Heating water for use in your home isn’t optional. Your family needs to bathe, you have dishes that must be washed, and you likely use hot water for other things around the house. Of course, all that heated water requires fuel, either gas or electric, and you’ll pay for each unit you use. The good news is that there are many ways to make your water heater more efficient to reduce the amount of energy it uses. One of the best options is a Maintenance Plan. How does maintenance save you money? Improved Heating One of the most important ways… Read more Unvented Cylinder No Hot Water: Help and Guidance for UK Homeowners 26 Mar 2024 When you open the tap, you expect hot water to flow. If it doesn’t, there is something wrong. But what is it? If you have an unvented cylinder and no hot water, this guide will help you troubleshoot the issue and get things back to normal as quickly as possible. 1. Check your cold tap. If you don’t have hot water from the hot tap, close it and open the cold tap. If you have no water from that tap either, then there’s a problem either with the mains themselves or with the mains connection to your home. Check with… Read more

Unvented Cylinder No Hot Water: Help and Guidance for UK Homeowners 26 Mar 2024 When you open the tap, you expect hot water to flow. If it doesn’t, there is something wrong. But what is it? If you have an unvented cylinder and no hot water, this guide will help you troubleshoot the issue and get things back to normal as quickly as possible. 1. Check your cold tap. If you don’t have hot water from the hot tap, close it and open the cold tap. If you have no water from that tap either, then there’s a problem either with the mains themselves or with the mains connection to your home. Check with… Read more Understanding the Parts of Your Unvented Cylinder 19 Mar 2024 If you have an unvented cylinder in your home, you know just how much of a difference it can make in your life. You get mains pressure hot water out of every tap and don’t have to deal with the issues that arise all too often from vented cylinders. How familiar are you with the parts that make up your unvented cylinder? In this post, we’ll introduce some of the components that help your cylinder produce hot water and protect you. Cylinder The cylinder is the largest component and the most obvious. This insulated cylinder holds the water to be… Read more

Understanding the Parts of Your Unvented Cylinder 19 Mar 2024 If you have an unvented cylinder in your home, you know just how much of a difference it can make in your life. You get mains pressure hot water out of every tap and don’t have to deal with the issues that arise all too often from vented cylinders. How familiar are you with the parts that make up your unvented cylinder? In this post, we’ll introduce some of the components that help your cylinder produce hot water and protect you. Cylinder The cylinder is the largest component and the most obvious. This insulated cylinder holds the water to be… Read more Tips to Make Your Unvented Cylinder More Energy-Efficient 12 Mar 2024 Running water has revolutionized the Western world. Having access to hot water at the turn of a tap is truly amazing. However, that comes with a cost. You pay money not just for every litre of water that flows through your home’s pipes, but also to heat that water. And when financial times get tight, everyone needs to find ways to cinch up their belts a bit. In this post, we’ll cover a few important ways to make your unvented cylinder more energy-efficient without sacrificing modern conveniences. Turn It Off The first tip we have to offer might seem a… Read more

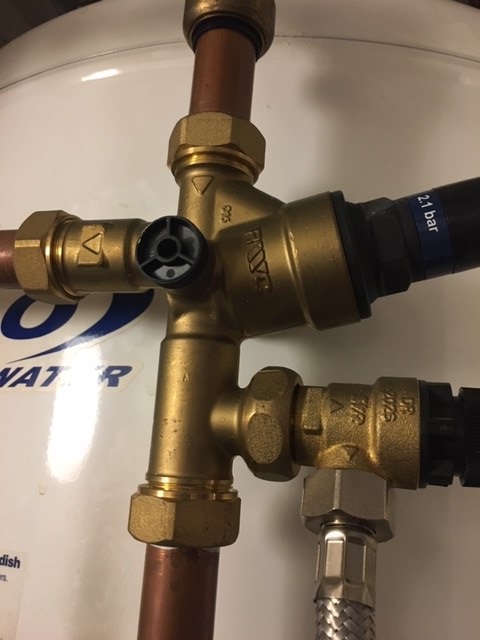

Tips to Make Your Unvented Cylinder More Energy-Efficient 12 Mar 2024 Running water has revolutionized the Western world. Having access to hot water at the turn of a tap is truly amazing. However, that comes with a cost. You pay money not just for every litre of water that flows through your home’s pipes, but also to heat that water. And when financial times get tight, everyone needs to find ways to cinch up their belts a bit. In this post, we’ll cover a few important ways to make your unvented cylinder more energy-efficient without sacrificing modern conveniences. Turn It Off The first tip we have to offer might seem a… Read more The Combination Valve: The Secret to Your Unvented Cylinder’s Success 27 Feb 2024 Your unvented cylinder is an important appliance. It’s what allows you to take luxurious hot showers and to wash up after eating. However, it can’t do its job without several other components all working together. One of the most critical is the combination valve. Not sure what the role of a combination valve is? We’re here to shed some light on that. What Is a Combination Valve? As the name suggests, a combination valve is an amalgam of several others. It serves many different but equally important roles in your water heater’s operation. What Does a Combination Valve Do? A… Read more

The Combination Valve: The Secret to Your Unvented Cylinder’s Success 27 Feb 2024 Your unvented cylinder is an important appliance. It’s what allows you to take luxurious hot showers and to wash up after eating. However, it can’t do its job without several other components all working together. One of the most critical is the combination valve. Not sure what the role of a combination valve is? We’re here to shed some light on that. What Is a Combination Valve? As the name suggests, a combination valve is an amalgam of several others. It serves many different but equally important roles in your water heater’s operation. What Does a Combination Valve Do? A… Read more Signs You Need to Replace Your Unvented Cylinder’s Combination Valve 20 Feb 2024 The combination valve is one of the most important components attached to your unvented cylinder. In fact, it’s crucial for safe operation. Like all components, it will wear over time and will eventually need to be replaced. If you don’t have regular maintenance, you’ll need to replace it much earlier than otherwise. But what are some of the signs to watch for that might indicate a need to replace your combination valve? A Lack of Hot Water Your combination valve includes a pressure-reducing valve. Its job is to reduce the pressure coming from the mains so that it is safe… Read more

Signs You Need to Replace Your Unvented Cylinder’s Combination Valve 20 Feb 2024 The combination valve is one of the most important components attached to your unvented cylinder. In fact, it’s crucial for safe operation. Like all components, it will wear over time and will eventually need to be replaced. If you don’t have regular maintenance, you’ll need to replace it much earlier than otherwise. But what are some of the signs to watch for that might indicate a need to replace your combination valve? A Lack of Hot Water Your combination valve includes a pressure-reducing valve. Its job is to reduce the pressure coming from the mains so that it is safe… Read more How Annual Maintenance Can Improve Your Unvented Cylinder’s Efficiency 6 Feb 2024 Unvented cylinders offer superior performance and reliability to older water heating options. They’re available in a range of sizes and capacities and can be installed almost anywhere in your home. However, despite all its capabilities and advantages, your unvented cylinder does require a little bit of care during its lifespan. Annual Services can help ensure that you avoid costly problems and catastrophes while improving your cylinder’s efficiency. Let’s discuss what you need to know. What Is Annual Maintenance? Most of your home’s appliances should be serviced, maintained, or at least inspected once or twice per year. For instance, your furnace… Read more

How Annual Maintenance Can Improve Your Unvented Cylinder’s Efficiency 6 Feb 2024 Unvented cylinders offer superior performance and reliability to older water heating options. They’re available in a range of sizes and capacities and can be installed almost anywhere in your home. However, despite all its capabilities and advantages, your unvented cylinder does require a little bit of care during its lifespan. Annual Services can help ensure that you avoid costly problems and catastrophes while improving your cylinder’s efficiency. Let’s discuss what you need to know. What Is Annual Maintenance? Most of your home’s appliances should be serviced, maintained, or at least inspected once or twice per year. For instance, your furnace… Read more What Is a Tundish? Understanding Unvented Cylinder Components 30 Jan 2024 Unvented cylinders offer reliable performance, peace of mind, and the steady stream of hot water you need at every tap in the home. However, because it’s a sealed, pressurised system, safeguards must be put in place to help prevent potential problems. One of those safeguards is called a “tundish”. What is it, and what does it do? What Is a Tundish? Technically speaking, a tundish is nothing more than a special type of pipe fitting. You’ll find them on unvented cylinders but also on boilers and other pressurised systems, where it’s important that you can check for leaks. What Does… Read more

What Is a Tundish? Understanding Unvented Cylinder Components 30 Jan 2024 Unvented cylinders offer reliable performance, peace of mind, and the steady stream of hot water you need at every tap in the home. However, because it’s a sealed, pressurised system, safeguards must be put in place to help prevent potential problems. One of those safeguards is called a “tundish”. What is it, and what does it do? What Is a Tundish? Technically speaking, a tundish is nothing more than a special type of pipe fitting. You’ll find them on unvented cylinders but also on boilers and other pressurised systems, where it’s important that you can check for leaks. What Does… Read more What Is a Combination Valve: Understanding Unvented Cylinder Components 23 Jan 2024 Unvented cylinders offer a steady flow of mains pressure hot water at every tap in your home. Gone are the days of dealing with low-pressure water at taps higher in the home or dealing with the maintenance challenges of a vented cylinder. However, that doesn’t mean that unvented cylinders don’t require maintenance. They do. You should have your unvented cylinder inspected and serviced at least once per year to make sure that it’s in good working order and to prevent unanticipated breakdowns with components, such as the combination valve. Not sure what a combination valve is or what its purpose… Read more

What Is a Combination Valve: Understanding Unvented Cylinder Components 23 Jan 2024 Unvented cylinders offer a steady flow of mains pressure hot water at every tap in your home. Gone are the days of dealing with low-pressure water at taps higher in the home or dealing with the maintenance challenges of a vented cylinder. However, that doesn’t mean that unvented cylinders don’t require maintenance. They do. You should have your unvented cylinder inspected and serviced at least once per year to make sure that it’s in good working order and to prevent unanticipated breakdowns with components, such as the combination valve. Not sure what a combination valve is or what its purpose… Read more Range Tribune Unvented Cylinders: Exploring the Benefits for You 2 Jan 2024 You have many options when it comes to purchasing an unvented cylinder for your home. However, the Range Tribune line is one of the most popular with customers throughout the UK. What gives it such staying power, and what should you know about it before making a purchase? Let’s explore Range Tribune unvented cylinders so you can make an informed decision. What Company Manufactures the Range Tribune Line? Range Tribune unvented cylinders are manufactured by Kingspan Water & Energy. The same manufacturer also makes Albion, Ferham, and Kingspan cylinders. What Makes Range Tribune Unvented Cylinders Worth Your Time? You want… Read more

Range Tribune Unvented Cylinders: Exploring the Benefits for You 2 Jan 2024 You have many options when it comes to purchasing an unvented cylinder for your home. However, the Range Tribune line is one of the most popular with customers throughout the UK. What gives it such staying power, and what should you know about it before making a purchase? Let’s explore Range Tribune unvented cylinders so you can make an informed decision. What Company Manufactures the Range Tribune Line? Range Tribune unvented cylinders are manufactured by Kingspan Water & Energy. The same manufacturer also makes Albion, Ferham, and Kingspan cylinders. What Makes Range Tribune Unvented Cylinders Worth Your Time? You want… Read moreJoanne, Warrington

8 January 2024

Annual Service

Richard, Bolton

14 December 2023

Annual Service

Brian, Wilmslow

15 December 2023

Annual Service

Waheed, Hertfordshire

1 January 1970

No Hot Water

Excellent service as usual.Despite the terrible weather and the lift being out of order

JUDITH, Glossop

28 December 2023

Annual Service

Peter, Liverpool

30 November 2023

Annual Service

Jonathan, Liverpool

22 November 2023

Replacement Valves

Dominic, Chorlton

6 November 2023

Heating Control Replacement

An excellent service as usual and Chris was very helpful and informative.

Derek, Chester

2 October 2023

Annual Service

© 2024 Country & Town Limited. All rights reserved EasyFlow is a Country & Town Limited service

Find out what our clients are saying about the services we provide

Click to view